120- 2800Bar high Pressure Hydro Jet Blasting shipyard cleaning 4 Blades rotary nozzles

25 May, 2025

38-22000psi Hydro Water blasting big tube cleaning machine BJV Nozzles

25 May, 202540-20k 40K Heat Exchanger UHP Waterjet Hydro-Jet Banshee Nozzles

Ultra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

- Product Introduction of Ultra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

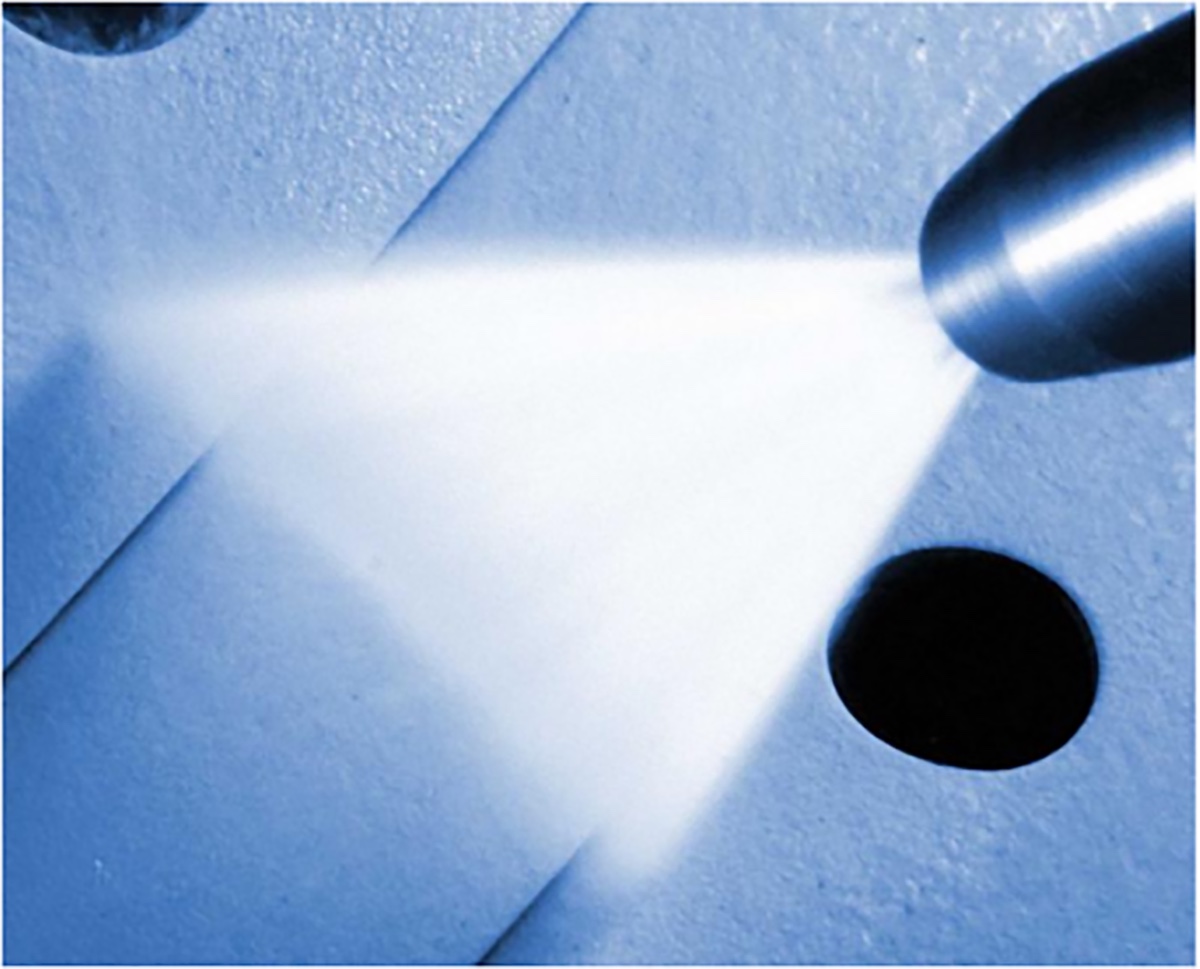

The Banshee nozzles is widely applied for heat-exchange cleaning and small diameter pipe and cleaning the pipe barrier etc, it is high-efficiency and easy-operation for small diameter pipe tube cleaning. We Panwin provide you various size of Banshee nozzles.

- Product Parameter (Specification) of Ultra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

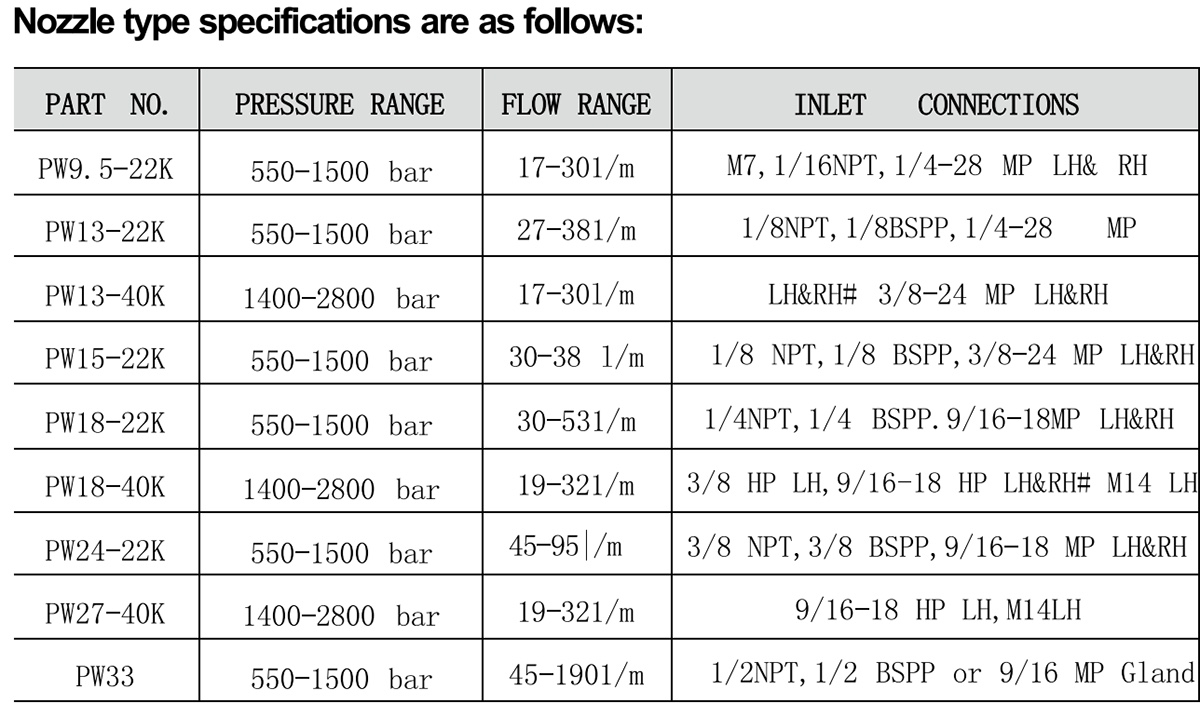

The hydro jets blasting Banshee nozzles is special designed for the heat-exchange, small

Diameter pipeline and pipe barrier, we have pressure range range from 550bar to 2800bar, biggest Flow rate is 190l/m, with various Inlet connection, it can applied to different tool for different pipeline cleaning case. And Specification details as follows:

- Product Feature And Application of Ultra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

Our small Pipeline hydro Jet blasting cleaning Banshee Nozzle is used for small pipe and tube, it is highest-efficiency pipe clean nozzles due to advantage features:

1:Unrivaled performance in cleaning and polish tube and small diameter Pipe, like heats ex-changer,small tube bundles.

2:SST Construction keep it durable and long-used in extreme condition.

3:High-effective to remove thin, hard scale, carbons, coke, and polymers.

Application:

The hydro Jet blasting cleaning Banshee Nozzle is designed and special used in small pipe, small diameter pipeline, tube, heat-exchange and small tub bundles.

It is high-performance, time-saving for small tube cleaning in water hydro blasting way.

- Product Details ofUltra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

- Product Qualification ofUltra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

Shenzhen Panwin Machinery&Equipment Co.,Ltd are a professional manufacturer specializing Hydro Jet Blasting Cleaning&Cutting machine parts,We strictly controls the whole process of product production according to the quality standard ISO9001-2015 and passed the quality Certificate, Years of experience in the production and design of Ultra-high pressure accessories and machinery, not only We are winning the trust and long-term cooperation of customers, but also accumulated rich design experience and industry sensitivity for us. We have been expanding and innovate to satisfy the market and customers needs and practical applications.

6.Deliver,Shipping And Serving of Ultra-high small Pipeline hydro Jet blasting cleaning Banshee Nozzle

We used the wooden case and all our wooden case are Plywood case or Wooden case is finished the fumigation treatment under the shipping requirement.

Every Wooden Case have the strong and firm feet about 7-10CM length, it is easy to forklift and transport goods.

Our spare parts are packed and covered some layers by the Waterproof,rust-proof and shock-Proof soft packing material, mainly the 3-5mm thickness foam film etc. We require our packing staff cover thick enough and wrap with the plastic film or adhesive tape tightly to ensure the packing can avoid almost any possible damage in the delivery process.

For the fragile,sensitive items, like Plunger, We have the solid plastic box cover some layer by the Waterproof,rust-proof and shock-Proof soft packing material, mainly the 3-5mm thickness foam film etc and wrap with adhesive Tape.

- FAQ

1:In the water Blasting cleaning process,What two factors is more important, pressure(bar) or Flow Volume(LMP)?

The two factors pressures and Flow Volume are both critically important for your optimized best cleaning performance and spray effect, the pressure will determine your spraying power, and the flows Volume take dirt and sediment etc away.

2:How important to keep the nozzles clean?

In the Water Hydro cleaning process, the blocked nozzle will not have good clean effect ,and the clogged nozzles also can increase the backward pressure on the power pump,and cause damage to the pump, so regular clean or even replace nozzles is important.