Some ideas for choosing the Pressure Water blasting cleaning machine parts nozzles

2024-03-28

In high-pressure water cutting and high-pressure cleaning operations and industries, it is very critical to choose a high-pressure nozzle suitable for cleaning machines and devices.

Generally speaking, choosing a suitable high-pressure nozzle you need to pay the attention to the follow aspect and factors.

First of all of course you need to pay attention to the dimension of the bore,and you need to know your machine what the maximum output PSI or BAR, how many gallons per minute (GPM) or Liters Per Minute (L/min) as well.

To know that borehole size is very important,because the dimension of the borehole is match and work together with air compressor to have best blasting and cutting production power. Too small or too big size borehole of nozzles will have no idea Ultra-high pressure spraying or cutting effect. If the 20/40Kpsi Pressure Water blasting Petrochemical pipe cleaning nozzles like M10 Nozzles size is too small, the potential spraying power cannot get through, if too big, it will lost the cutting or spraying power potential.

Secondly, the structure and shape of the nozzles is also crucially important for Water-jet high pressure industry cleaning, and plays an critical role in its water blasting effect.

Generally, there is straight nozzles Type and de Laval nozzle Type.

The straight nozzle generate a pinpointed and vertical jet stream,and it is ideal for removing paint, rust, tar, concrete, and other hardened substances. The air compressor funnels air into the bore, where it compresses and accelerates along with the abrasive material straight out the other side. And de Laval nozzle Type feature is on the bore size, in the De Laval nozzle, the bore dimension is narrows fist and then widens again, in this way to have the best spraying effect, but it is applied in some device.

Thirdly, you should check the nozzles material. The Water hydro blasting Vessel cleaning machine spare parts Nozzles mostly are made of carbide, a combination of carbon and a metal like stainless steel, good quality nozzles with harden material can have better spraying effect.

The forth aspects and factors of the spraying effectiveness and power will the degree of the spray. And the degree of the spraying can be explained to what angle of the ultra-high water radiates.such as a big-cover spray with an angle of 65 degrees has much lower pressure than a 0-degree spray. The smallest degrees usually apply to large-scale water blasting projects, such as rust removal or industrial cleaning.

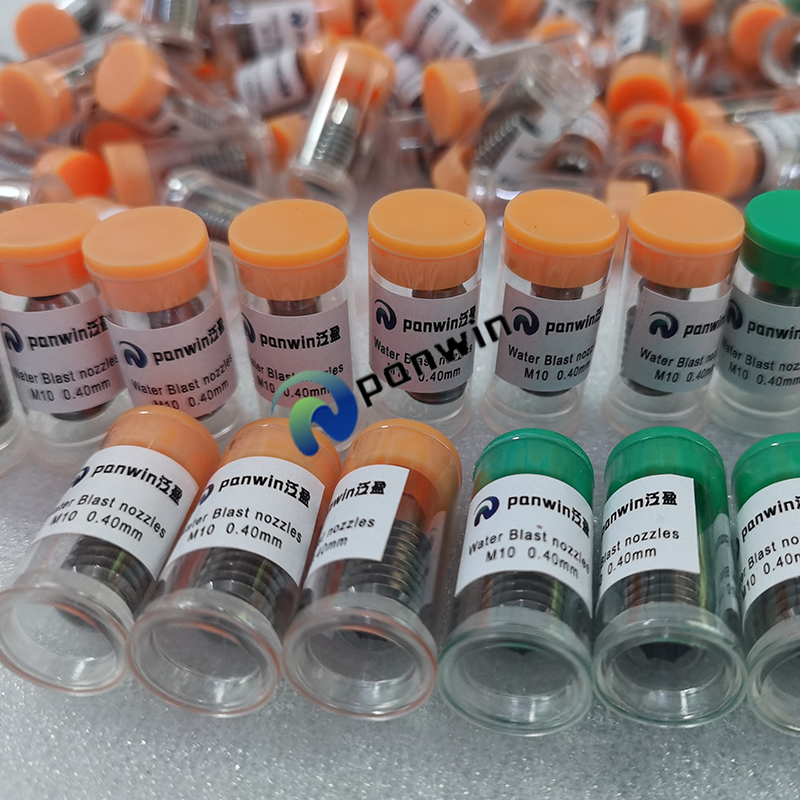

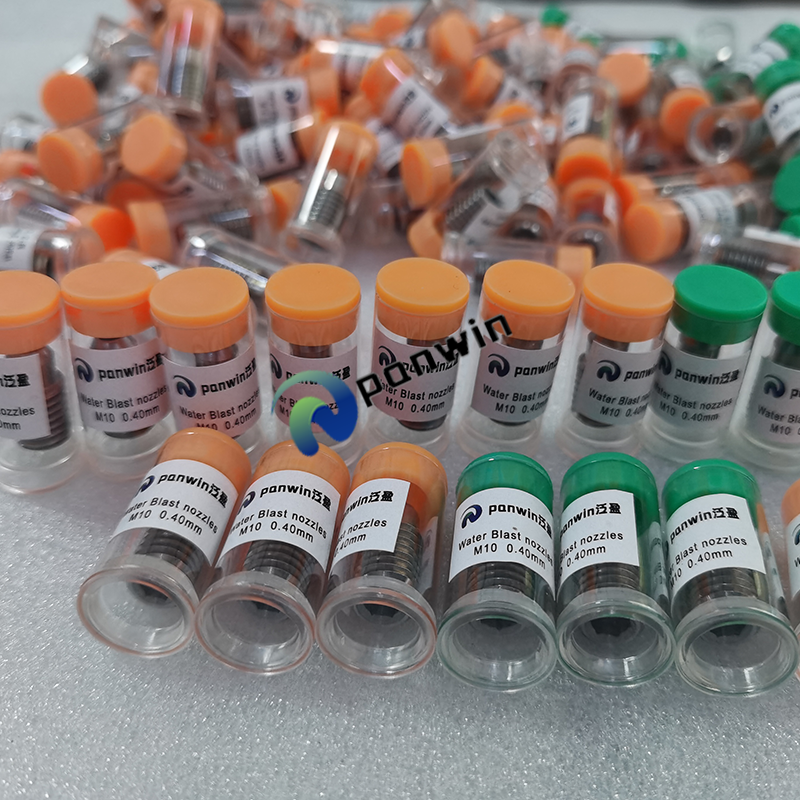

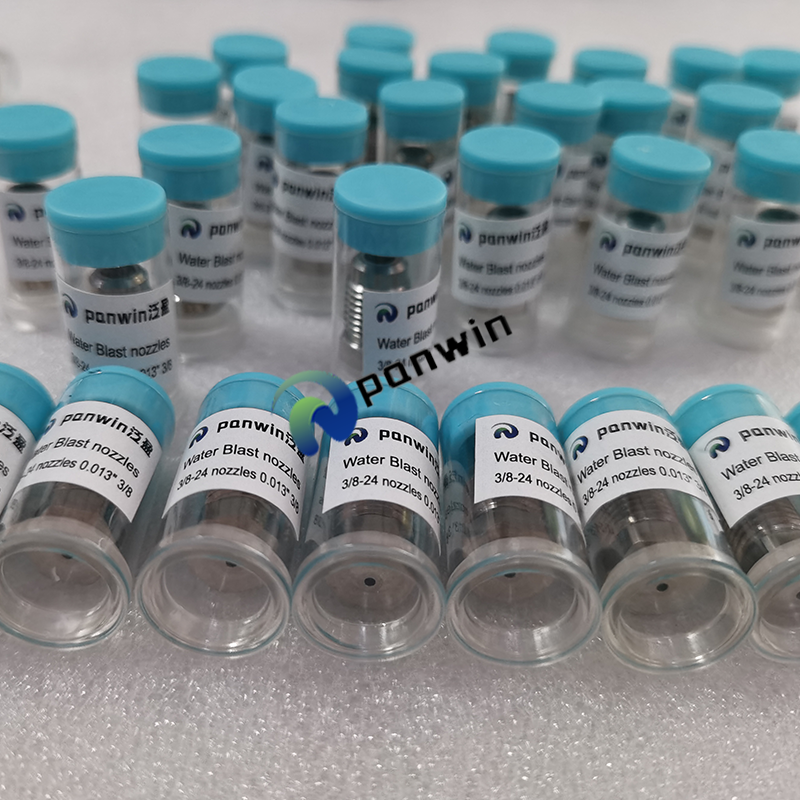

We Panwin provides our customers Water blasting Ship Surface cleaning parts machine parts Nozzles for different pressure level, our nozzles is UHP Rated up to 55Kpsi, with 3/8-24 UNF thread connection, it can insert in the rotary nozzles and spray-bars, the nozzles body heat-harden treated, and Superior sapphire material, it is long-life and high-quality.

RELATED NEWS

-

High Pressure Water Removal Of Road Water Lines

UHP Plunger Pump Water Jetting Road Painting strip removal of hydrographic lines or plastic and rubber lines refers to the use of high-pressure water cleaning nozzles to remove water lines on the road surface.

-

Ultra-high Pressure Water-Jetting Pressured Triple Plunger Pump Water Blasting Aluminum concrete Formwork Semi-Auto Clean System Optional

The advantages of aluminum concrete Formwork and modules for construction are that, the Aluminum formwork have few joints, high precision, short cycle, high efficiency, and multile recycling.

-

UHP Hydro-Jetting Pressured Triple Pump Water Blasting Aluminum Cement concrete Building Formwork Semi-Auto Cleaning System Introduction

We introduce our UHP Hydro-Jetting Pressured Triple Pump Water Blasting Aluminum Cement concrete Building Formwork Semi-Auto Cleaning System.

-

Blasting Aluminum Cement concrete Building Formwork Semi-Auto Cleaning System

For most aluminum formwork manufacturers or construction units, high-pressure Semi-Auto cleaning of building cement aluminum formwork construction is generally more favored by manufacturers because Aluminum Forworks has the advantages of flexible operation, high efficiency, etc features.

-

UHP water Blasting Jetting Aluminum Alloy formwork cleaning Proposals

Aluminum formwork building formwork is increasingly used in the construction industry because they have many great advantages.

-

UHP 3000Bar Ultra-high pressure Water Blasting machine Pipeline Tubing Cleaning

UHP Hydro-Jetting Water Blasting Industrial pipeline cleaning is a very large and practical cleaning project.

-

Brief Talk On 20kpsi-40kpsi Uhp Hydro-Jet Triplex Plunger Pressurized Cleaning Equipment Parts Pump Pressurized Cleaner Concrete Cements Cleaning

In the municipal cement road cleaning and maintenance project, 40kpsi waterjet cleaning equipment hammelmann high pressure Hydro Jet Concrete machine high-pressure water jets are widely used in removing water lines and cleaning.

-

Uhp Water Blasting Triplex Plunger Pump High Pressure Water Jet Equipment Ship Surface Treatment System

UHP high pressure Hydro Jet Ship Hull Surface blasting cleaning process is the new trend for Ship hull cleaning washing refurbish industry.

-

UHP Water Blasting Triplex Plunger Pump High Pressure Water Jet Equipment Ship Surface Treatment System Introduction

The ship surface treatment system includes power source, high-pressure water transmission pipeline, automatic and semi-automatic cleaning mechanism and recovery system.

-

UHP High Pressure Water Jet Ship Hull Cleaning Equipment&Water-Blaster Is New Trend

Traditionally,in the ship washing and cleaning industry, the sandblasting jet cleaning industry used to occupy a large market share.

-

The Uhp 20kpsi Water Blast Pressurize Triplex Plunger Pump Aluminium Formwork Cleaning Machine System

The aluminium formwork system is a building system used to form cast-in-place concrete structures of buildings. This formwork is made of aluminium alloy, which has high tensile strength and is very hard.

-

1500bar High Pressurized Reciprocating Rotating Cleaning Mechanism Fat

We are very grateful to our customers for their confidence in 1500Bar pressurized cleaner rotary nozzles and trust in our High pressurizing washer rotary nozzles.

-

Daily Shipent Aug 12th 2024

Thank you very much for your trust and cooperation. The order will be shipped on time today. It will be shipped,including DN8 2800Bar Pressure Water Jet Blasting cleaning machine parts high-pressure hoses roll 20Meter*4,DN5Shipyard Surface Water Jet Blasting cleaning machine parts UHP hose.

-

Uhp Water Blasting System Cleaning Job Case Study

Customer have the surface cleaning of Perforated Stainless Steel-Perforated Drum requirements and frequently need the water blasting cleaning request, pressurized cleaner Jobs need the UHP water blasting pump and pressurized washer pump rotary cleaning nozzles mechanism.

-

2024 Aug Shipment of APW Waterjet Cutting Parts

2024 August first week, Thanks for customer order for APW waterjet parts and specially the Waterjet Abrasive nozzles.

-

Daily Shipment on July 27th 2024 of UHP Hydro Blasting cleaning equipment parts-high quality M10 3/8 Nozzles Type3546

On the Forth Week of July 2024, We ship out the 20Kpsi Pressure Water blasting chemical industry cleaning machine components 3-8-24 Nozzles and the Water blasting Petrochemical pipe cleaning machine parts M10 Nozzles,combined 1500pcs.

-

Uhp Water Blasting System And Hydro Jet Cleaning Mechanism

UHP water Blaster cleaning machine system is cleaning system to uses water as the medium and water is pressurized to various pressure rated by the Triplex pump to the UHP hose to the various Ultra-high pressure cleaning mechanism according to the different cleaning object and object condition.

-

The Air Pre-heater Cleaning Device

The UHP Hydro Water blasting Air pre-heater cleaning is critically important for Power plants to restore and optimize the efficiency of APH.

-

Compact High pressure Portable Water-jet Coal Mine Cutting Case Introduction:

Compact high pressure water-jet Portable cutting process is the Cold clean cut without the risk of explosion or cause inflamed, and also the high-pressure water-jet cutting (also known has hydro cutting) supercity which it doesn’t generate heat, stress or distortion in materials, the High pressure Portable abrasive water-jet Concrete Steel plate cutting machine widely applied in waste tank hole cutting, gas pipeline cutting, line of intersection and profile cutting, and the sheet plate cutting etc.

-

Compact High pressure Portable Water-jet cutting unexploded aerial bomb Cutting Case

The portable water jet cutting machine have huge flexibility, because it can be designed the various kind of Holding Kit and On/Off Valve, like magnet walking car,Chain Pipe holding car,Radius circle cutting tool, spider holding Tool.

-

Compact Portable Water Jet Cutting Cut case

Compact portable water jet cutting machine is Clean cold cutting device using ultra-high pressure Abrasive water jet, due to Lightweight body Compact design so it is very flexible and convenient, it is very suitable for crude benzene tank cutting due to Benzene Tank is crude benzene residue inside, and there are many impurities at the bottom, because is is cold cutting and free flame.

-

What are the main components of Water Jet Cutting Machine?

Water Jet Cutting Machine is a machine that uses high-pressure water jets or water jets mixed with abrasives to precisely cut materials. Waterjet cutting technology is widely used in various industries, including metal cutting, stone cutting, rubber cutting, etc.

-

Principle analysis of high-pressure water gun cleaning machine

High-pressure water gun cleaning machine is a common industrial cleaning equipment. Its principle is based on the generation and utilization of high-pressure water flow. The following will provide a detailed analysis of the principle of high-pressure water gun cleaning machine to help readers better understand its working mechanism.

-

Panwin creates innovative water jet cleaning machine parts, leading the new trend in the industry

Recently, Panwin, the world's leading provider of industrial cleaning solutions, once again set off an industry trend and released a series of innovative water jet cleaning machine parts to provide users with a more efficient and reliable cleaning experience. The launch of this series of parts marks a new breakthrough for Panwin in technological innovation and product research and development, and will further consolidate its leading position in the global cleaning equipment market.

-

Ultra-High-Pressure Water Jet Cleaning Machine: Revolutionizing Dirty Work

In the world of cleaning, some jobs are dirtier than others - think industrial facilities, oil rigs, and even aircraft engines. These environments are notoriously difficult to clean, often requiring hours of grueling, labor-intensive work. But now, a new technology is revolutionizing the cleaning industry, making even the dirtiest jobs quick and easy: the Ultra-High-Pressure Water Jet Cleaning Machine.

-

Ultra-high pressure waterjet components: the quality choice

In recent years, ultra-high-pressure water jet technology has emerged in the industrial field and is widely used in processing and manufacturing in various industries. Behind this technology, high-quality ultra-high-pressure water jet components play a key role. The precision manufacturing and excellent performance of these parts have become an important guarantee for ensuring the stable and efficient operation of ultra-high-pressure water jet equipment.

-

Compact High pressure Portable abrasive waterjet chemical plants Tank cutting machine

Compact Portable High pressure abrasive waterjet chemical plants Tank cutting machine is a cold cutting device using ultra-high pressure water jet, so it make no open flame, no high temperature, no hazardous gas odor, no stress or distortion in your materials, so it is superior advantage in many occasions such as waste tank hole cutting, gas pipeline cutting, line of intersection and profile cutting, and the sheet plate cutting, which is in the wield surroundings for inflammable and explosive, and potential dangerous or hazardous risk.

-

Daily Shipment on Nov 22nd,23th 2023 of Compatible Jetstream 4240 High quality parts &Rotary nozzles set

On the Forth Week of November 2023, We Thank you for our customer trust and order, and constantly creating more values for our partners with higher quality and efficiency is our company ever-going pursuit

-

The Ultra-high Pressure Water blasting surface cleaning machine rotating UH Swivel nozzles Introduction

The Ultra-high Pressure Water blasting surface cleaning machine rotating UH Swivel nozzles is an efficient cleaning equipment that is vastly applied in various industries and fields. The Water blasting rotating UH Swivel nozzles generates strong impact through high-pressure water flow, which can effectively remove dirt, dust and debris on the surface of objects. At the same time, the rotor inside the nozzle can rotate. , cleaning with wider coverage and improving cleaning efficiency.

-

What is ultra high pressure water jetting?

Ultra-high-pressure water jetting is an industrial cleaning and cutting technology that uses extremely high-pressure water to clean surfaces, remove dirt, or cut materials. This technique typically uses specialized water jet equipment to spray a stream of water onto the surface or object that needs to be treated by increasing the water pressure to extremely high levels (usually between 10,000 psi and 90,000 psi).

-

Solution to the problem that the water jet cannot be discharged into the water

In water jet cutting operations, sometimes the water jet cannot enter the water. This situation may involve the water source, water pump, nozzle gem or control system. Following info will introduce the general solutions:

-

Use of ultra-high pressure water gun cutting in industry

Ultra-high pressure water gun cutting technology is a cutting process widely used in the industrial field. It uses a high-pressure water stream and a mixture of abrasives to cut a variety of materials, including metal, stone, glass and composites. Ultra-high-pressure water gun cutting technology has the advantages of high precision, environmental protection, and safety, so it has been widely used in aerospace, automobile manufacturing, construction, stone processing and other fields.

-

The Application of the Ultra-high Pressure Water Jet Blasting machine Plunger booster Pump in Industry

The Ultra-High pressure plunger pump is a kind of mechanical equipment widely used in industrial fields. Its application fields cover many industries. The following introduction will bring out the application of high-pressure plunger pump in various fields in detail.

-

Ultra-high pressure Triplex Bare-shaft water blasting cleaning pump Fluid End Assembly Steps

The Ultra-high pressure Triplex Bare-shaft water blasting cleaning pump Fluid end assembly is an important part of the hydraulic system. Its assembly process requires strict operating procedures and precautions. The following are the detailed steps for assembling the Ultra-high pressure Triplex Bare-shaft water blasting cleaning pump Fluid end assembly:

-

Winter Precaution and measure for Ultra-high pressure Water blasting machine Pump

In Winter days, to ensure normal operation and maintenance of the Ultra-high Pressure Water Jet Blasting cleaning machine Triplex Pump, it requires the special attentions and precaution to some specific matters, some points as follows need to be note and carry out:

-

High Pressure Portable Water-jet cutting Tooling Sets introduction 2

Compared with traditional high pressure Water-jet cutting Table machines with CNC control system and control box, Ultra-high portable water-jet cutting machines have great advantages for outdoor cutting.

-

Compact Portable High pressure abrasive water-jet Tooling Introduction

High pressure Portable water-jet cutting machines, because they are small in size&weight,and high portability, and The water-jet Vessel Tank cleaning&Cleaning machine can be designed different work equipment and tooling according to different working conditions, and the mobile hydro-Jet high pressure Water-jet has great advantage in cutting as it make no open flame,no high temperature,no hazardous gas odor,no stress or distortion in your materials,and therefore the High pressure Portable water-jet chemical plants Tank cleaning machines is suitable for field operations and cutting industries,Like chemical plants Tank,gas stations,Coal mining site operation, construction site reinforced concrete cutting, etc

-

Compact Portable High Pressure Abrasive Water-Jet Reinforced Concrete Cutting Machine

The compact portable water jet cutting machine is a clean cold cutting device using ultra-high pressure Abrasive water jet, due to Lightweight body compact design, so it is very flexible and convenient.

-

How To Select The Correct Ultra-High Pressure Hydro-Jet Blasting Cleaning Machine Hoses

The mobile and portable hydro-jet ultra-high pressure chemical plants tank cleaning machine high-pressure hose is a very important component of the high-pressure spraying cleaning equipment.

-

Compact High pressure Portable Water-jet cutting &Cleaning

Compared with traditional three-axis and four-axis high-pressure water cutting machines with the fixing working table,Compact portable water jet cutting machines have unique and incomparable advantages for on-site construction cutting, chemical plants tank cutting, dust removal, special for the chemical tank, which contains the flammable and explosive material, like Oil Tank, gasoline Benzene etc tanks container or Tube, cleaning, rust removal etc other operations.

-

What does high pressure water jet do?

High-pressure water jet, also known as water jetting or hydro-jetting, is a technique that utilizes a highly pressurized stream of water to perform various tasks. Here are some common applications of high-pressure water jets:

-

Daily Delivery Sept-2023-60kpsi 5 Axis Waterjet Cutting Machine Parts Kmt Shock Attenuator.

Today we sent the sets of the KMT shock attenuator to our customer. Every customer's trust is our goal. Based on the business principles of mutual benefit, we create good business relationships.

-

What is high pressure water jetting?

High-pressure water jetting, also known as water blasting or hydro-jetting, is a technique that uses a stream of pressurized water to remove dirt, debris, coatings, and other unwanted materials from various surfaces.

-

High Pressure Water Blasting: A Powerful Cleaning Technique

High-pressure water blasting is a powerful cleaning technique that offers numerous benefits for various industries and applications. With its ability to deeply clean surfaces, versatility, environmental friendliness, and non-destructiveness, it has become a preferred choice for heavy-duty cleaning tasks.

-

Water Jet Cleaning: An Effective Cleaning Solution

Cleaning is an essential part of our daily lives, whether it's for industrial equipment, infrastructure, or household surfaces. Water jet cleaning, also known as hydro-jetting or water blasting, has gained significant popularity as an effective and efficient cleaning method. By utilizing high-pressure water streams, water jet cleaning offers numerous advantages over traditional cleaning techniques.

-

Waterjet Washer Parts: A Key Component for Efficiency and Reliability

The parts of the water jet cleaning machine are the key components for its efficient work. The excellent design and manufacture of nozzles, high-pressure pumps, water tanks and filters, and control systems can provide stable and efficient cleaning effects while ensuring the reliability and safety of equipment. Only with high-quality parts and proper maintenance and maintenance can the water jet cleaning machine perform at its best and meet the needs of various cleaning tasks.

-

Water Jet Washing Machine Parts Manufacturer Panwin: High Quality and Innovation Driven Industry Leader

Panwin, a water jet cleaning machine parts manufacturer, has become a leader in the industry through its excellent quality control system, technological innovation and R&D capabilities, customer-customized services, and awareness of sustainable development and environmental protection.

-

SC Self-Rotary Nozzles Manual-Panwin

The SC self-rotating surface cleaning tool is the hot-sale product in our products list, it has the powerful spraying performance and easy service features, its stable working cleaning is welcomed by our customers, and following is the manual for service and maintenance works.

-

2800bar Pressure Water Jet blasting SC Self-Rotating Surface Cleaning Tool testing

The SC self-rotating surface cleaning tool is the hot-sale product in our products list,it has the powerful spraying performance and easy service features, It is a powerful surface cleaner with magnetic braking system installed on the spray gun.

-

The Water Jet Blasting Cleaning Machine Pump Precaution

The Hydro Jet Blasting Cleaning machine pump is a high-pressure operating equipment. It needs the general safety precaution process to ensure both the operator and machine safety.

-

Water jet cleaning machine parts: a key component to improve cleaning efficiency

Waterjet cleaning machine is an efficient and environmentally friendly cleaning equipment, which is widely used in various industries. The Water Jet Cleaning Machine Parts play a key role, and their quality and performance directly affect the cleaning effect and the reliability of the equipment.

-

What Is Water Blast Cleaning?

Water blast cleaning, also known as "Hydro blasting", is a chemical-free, environmentally-sound, and workplace-safe cleaning technique.

-

Water Jet Blast Cleaning Benefit

Water jet blast cleaning is widely used in industry cleaning, and water blast cleaning has many advantages compared with the common cleaning methods, and we have mentioned the advantage of water jet cleaning methods ways below.

-

Tank & Vessel Water Jet Blasting Cleaning

The Tanks, Vessels and Tankers are the important containers to carry and deliver the Oil and Petrochemicals etc hazardous and stubborn Substances. However, as time goes by, the fossil fuels and their derivatives, typically petrochemicals in the tanks and vessels, will become dregs.

-

Water Jet Blasting VS Sandblasting Surface Cleaning

In the water blasting industry cleaning application, surface preparation is an important job when you plan to do a painting on the material surface. It has to be handled correctly because it affects the service life, quality, and performance of the paint job.

-

Hydro Jet Blasting Pipeline Cleaning

Water Jet blasting piping cleaning process covers a wide range of industries, including power and petrochemical, marine and offshore, construction and infrastructure, municipality and wastewater, mining industry, and facility management.