UHP Hydro-Jetting Pressured TriplePumpBlasting Aluminum Cement concreteBuilding Formwork Semi-AutoCleaning System

17 September, 2025UHP Water Blasting triplex plunger pump high pressure water jet equipment Ship surface treatment system Introduction

17 September, 2025UHP Hydro-Jetting Pressured TriplePump Water BlastingAluminum Cement concreteBuilding Formwork Semi-AutoCleaning System Introduction 2

We introduce our UHP Hydro-Jetting Pressured TriplePump Water Blasting

Aluminum Cement concrete

Building Formwork Semi-Auto

Cleaning System

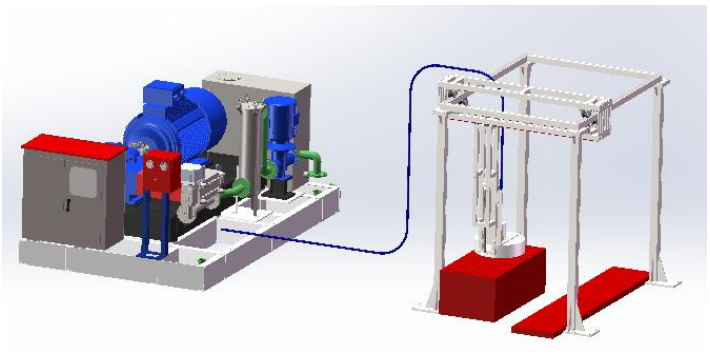

This Semi-auto cleaning system consists of Four Unites:

A) high-pressure water jet pump station,

B) high-pressure hose,

C) truss-type three-axis track system

D)UHP cleaning Plate or Disc

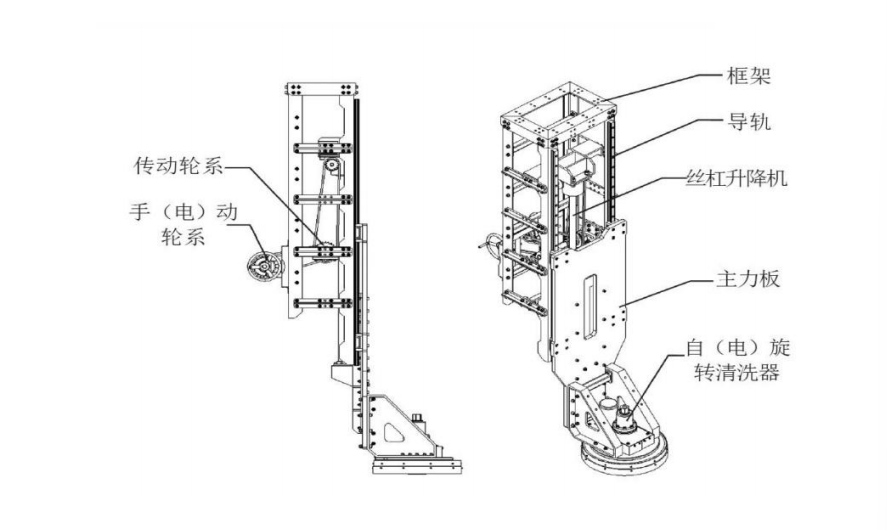

For the Track System the operation Features is:

During the UHP 22KPSI Water Blasting Aluminum scaffold and concrete Formwork Cleaning Semi-Auto cleaning machine System operation, the aluminum alloy Formwork and template is stacked on the flat ground inside the truss frame, and the UHP Water-Jetting cleaning target distance is adjusted by adjusting the lifting and cleaning mechanism.

The lifting and cleaning mechanism can be pushed manually, and under the action of the guide wheel, Blasting Aluminum Cement concrete Building Formwork Semi-Auto Cleaning System it slides forward, backward, left and right along the track inside the truss frame.

The UHP 22KPSI Water Blasting Aluminum scaffold and concrete Formwork Cleaning Semi-Auto cleaning machine System have many advantage:

Firstly,there is not harm or damage for the Aluminum scaffold and concrete Formwork.

The High-pressure water is used for cleaning,which will not damage the aluminum alloy template after cleaning, and the discharge is safe, and will not affect health and pollute the environment.

Secondly:High Safety level for the operators and personnel:

When the operator is working, he is far away from the high-pressure waterway, avoiding the danger of manual gun holding.

Thirdly, High Cleaning Efficiency:

The cleaning area is large and the cleaning speed is fast, which improves the cleaning efficiency.

Take the following videos operation:

Cleaning efficiency: 3 people: 240-300㎡, both large and small panels,

Only cleaning large panels (standard): 600-700㎡/10 hours

Fourthly,easy to operator and user-friendly Operation.

The lifting and cleaning mechanism can move by manual pushing, which reduces the fatigue intensity of the operator for long-term operation

Advice for Aluminum Cement concrete

Formwork

The largest plane of Aluminum Formwork is in contact with the concrete and needs to be thoroughly cleaned so that the poured concrete surface is very flat. The other four planes are in contact with other aluminum alloy modules and also need to be cleaned, otherwise the concrete will easily bulge or become uneven. Therefore, we recommend purchasing 2 sets of equipment.

One set is used to clean the front and back, and the other set is used to clean the sides or ends. It can also be equipped with a handheld gun with a rotating nozzle to clean two narrow ends and long ends. It can be cleaned sideways.

We provide the Aluminum Cement

concrete Formwork Semi-Auto and Full-Auto and production line solution for you at