Daily shipment of our 2800Bar Hydro-Jetting Heat Exchanger UHP Cleaning Anti-withdraw Devices

2 November, 2025Introduction Of Ultra-High Pressure Rust Removal Head and Rust Removal Spray Disc

10 November, 2025A brief discussion on Future Development Trends of 2800Bar High-Pressure Water Jet Rust Removal Device

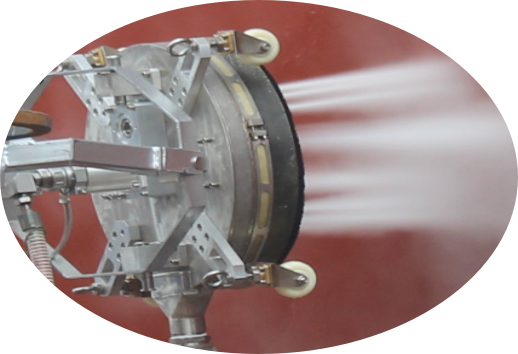

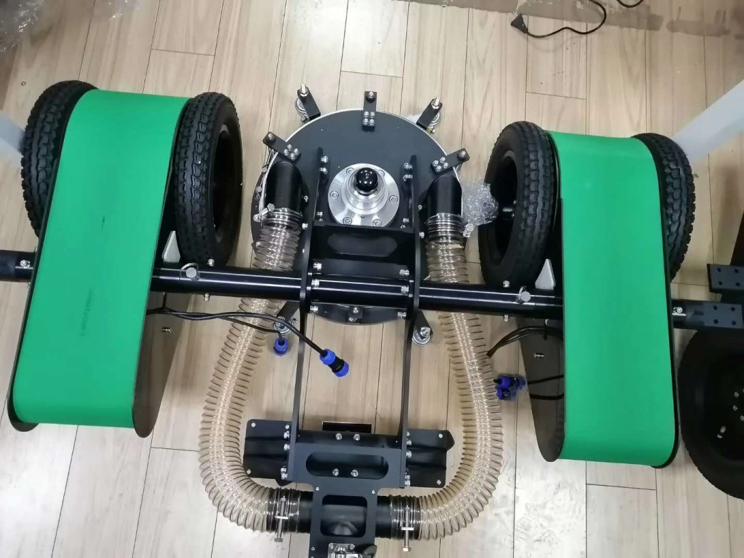

Ultra-high pressure or high-pressure water jet rust removal has significant advantages, both in terms of environmental protection and increased work efficiency, making it ideal for ship washing, cleaning, and metal surface treatment etc. Currently, typical wall-climbing ultra-high pressure robots operate at pressures of 2800 Bar, achieving rust removal efficiencies of 40-60 m²/h and a rust removal grade of Sa2.5. They are suitable for complex structures such as curved surfaces and welds, and are highly effective on the inner and outer walls of oil tanks or ship hulls. High-pressure water jet rust removal is a major trend in high-pressure cleaning operations. Regarding the future development of this technology, we would like to offer a few thoughts:

- High-pressure water jet technology can be combined with other high-tech methods to form mechanized and intelligent high-performance rust removal equipment or methods.

For example, combining it with robotics and CNC technology can create mobile, efficient, and easily controllable water jet rust removal equipment.

- Develop new jet forms and optimize jet composition.

From high-pressure continuous water jet rust removal and ultra-high-pressure continuous water jet rust removal to high-pressure abrasive water jet rust removal, some problems have emerged over time: high pressure leads to expensive equipment, easy damage, uneven abrasive delivery, easy clogging, unsafe manual operation, and secondary pollution caused by the inability to recycle abrasive.Therefore, it is necessary to introduce new high-pressure water jets, such as cavitation water jets, pulsed water jets, and ultrasonic water jets, to reduce rust removal pressure, extend equipment life, and improve equipment safety.

- Prevent rust re-emergence.

The high-pressure water jet rust removal process forms a water film on the substrate surface. If not treated in time, it will lead to rust re-emergence on the substrate. Therefore, by designing a vacuum composite high-pressure robot rust removal equipment, it has been successfully applied to rust removal operations in fields such as shipbuilding. Vacuum extraction of rust slag allows for immediate removal and drying, preventing rust recurrence to a certain extent. However, this also results in drawbacks such as the equipment’s large size and inconvenient movement. Therefore, how to effectively prevent rust recurrence is a pressing issue for waterjet rust removal.

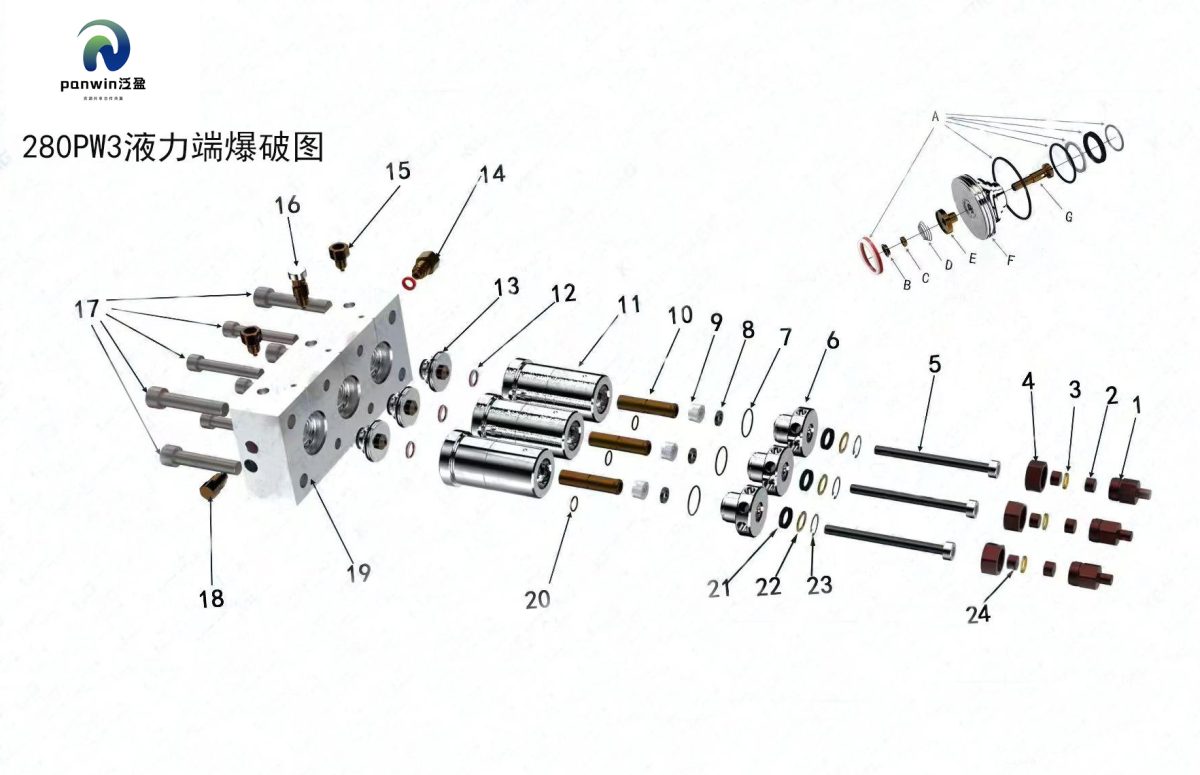

(4) Improve rust removal efficiency and quality, and optimize key components of the rust removal system. Whether it’s abrasive waterjet rust removal or cavitation waterjet rust removal, the key component of the rust removal system is the nozzle. When the pressure is constant, the optimization of the nozzle structure is directly related to the rust removal efficiency and quality. Therefore, nozzle structure optimization design is a key technology for waterjet rust removal.

With increasingly higher environmental protection requirements,high-pressure waterjet rust removal technology, characterized by green environmental protection, high efficiency, and safety, will become mainstream.

Currently, high-pressure waterjet rust removal technology is developing towards mechanization and intelligence.In the future, waterjet rust removal technology will develop towards pollution-free pure water rust removal, with huge development potential.